We have our own marking department in Poland.

We work using only brand-name machines and components.

Laser engraving

The method is used for permanent marking on metal, leather, wood and plastic objects. The digital logo is sent to a laser engraving machine. By using a beam of light, the top layer of the marked object is ” burnt” and the logo becomes visible. Created engraving is permanent and indelible.

Metal, aluminum (the color of the engraved logo is close to white), wood (it is a natural product, so not every engraving will be the same), hard plastics, leather.

Pad printing

Pad printing is an intermediate printing method. A logo is reproduced on a metal plate (matrix). This causes the graphic to “sink” into the upper layer of the matrix. The deeper part is filled with ink. A smooth stamp made of silicone rubber takes the ink and transfers it to the printed surface. This is the most widely used printing technique in the advertising industry.

Metal and aluminum, plastics, PVC, wood, cardboard.

With pad printing, the ink remains on the surface of the material. This means that the print may get scratched if rubbed against sharp objects like keys, knives

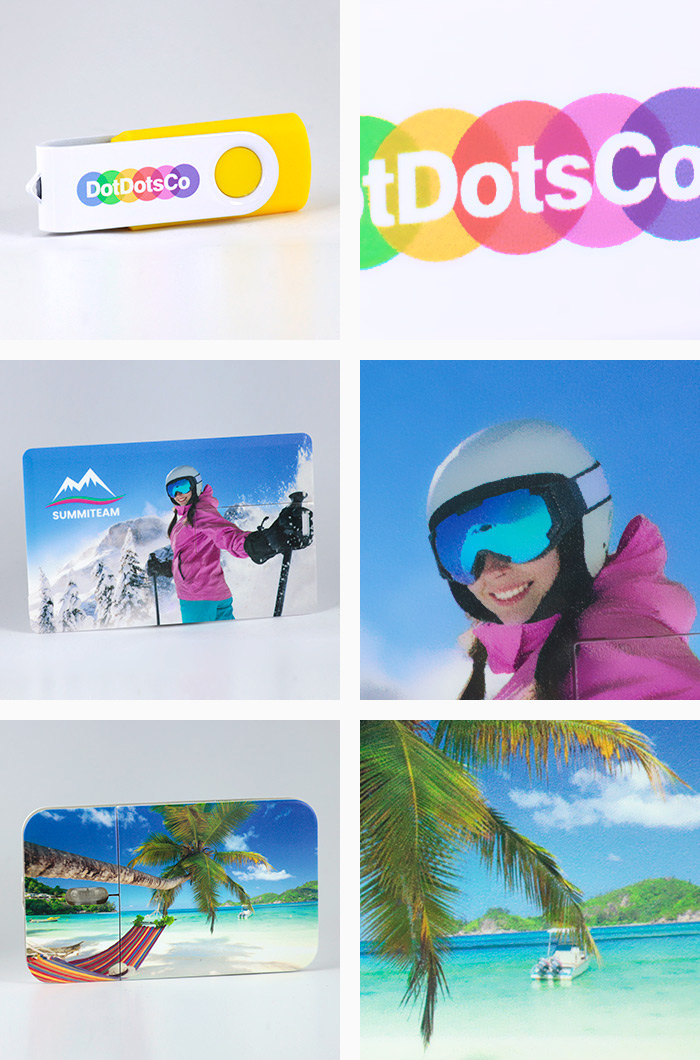

Full-color print

It is made in CMYK digital printing technology. The printing plotter prints directly on the item. Precision computer-controlled heads move over the printed surface to create the image. At the same time, UV lamps fix the ink – the technique allows to make a very durable print. Thanks to the work in the CMYK digital color palette and very high resolution, the print has the greatest number of details, giving the effect of a “photo”.

Metal and aluminum, plastics, cardboard.

Doming - 3D sticker

The term “doming” comes from “a rounding that resembles a dome.” A logo is digitally printed on the self-adhesive material . The desired shape of the sticker is cut out on the plotter, and then a layer of polymer resin is applied to the surface. This layer is crystal clear, so that the logo is not only protected from staining and scratches, but also looks slightly enlarged and highly decorative.

Selected aluminum and plastic memory models.

Embossing

The logo is etched on a metal stamp and then pressed into the material of the item. The material must be resistant enough to withstand the pressure of the machine, and the surface must be even and flat.

Leather and leather-like materials.

Illuminated logo

The special engraving is illuminated from underneath by LED.

Selected models of computer mice

Original and unique marking effect

Data uploading

Our USB flash drives can be supplied with uploaded content such as presentations, catalogs, videos, promotional and teaching materials, etc.

Packaging personalization

We offer a wide selection of marking and personalization methods for our packaging.

A full range of box designs and patterns can be found in the BOXforUSB catalog.

Laser engraving

Elegance, durability and premium effect.

Available on metal Tinbox type packaging.

Pad printing

Precision of color and detail reproduction.

Available on virtually all packaging models, both cardboard (Giftbox, Casebox, Coverbox, Cardbox) and metal (Tinbox).

Full-color print

Photographic quality and full-color.

Available on all packages with “Print” (Giftbox Print, Casebox Print, Coverbox Print, Cardbox Print and Easybox Print).

Glossy / matt film

“Print” boxes can be finished with high quality foil in two types:

Hot stamping

Luxury marking method of embossing the mark together with gold or silver foil. Available on packaging: Giftbox, Casebox, Coverbox, Cardbox, as well as Easybox.